Resources

Our team is dedicated to providing industry-leading information.

Featured Resource

Guide to SPCC Planning

This information-packed guide includes:

- Who is regulated

- Building your plan

- Spill prevention

- And more

Get The Guide

One-Pagers

Outfall Inspection App

Learn how an outfall inspection app can help you track everything from your smartphone to satisfy MS4GP requirements....

Get the One-Pager

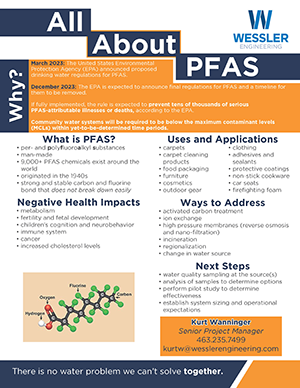

One-Pagers

All About PFAS

Learn all about PFAS and how it effects water systems and ways to prevent it....

Get the One-Pager

One-Pagers

Do You Need a Stormwater Utility?

Why form a stormwater utility? How do you identify stormwater management needs? What are some next steps?...

Get the One-Pager

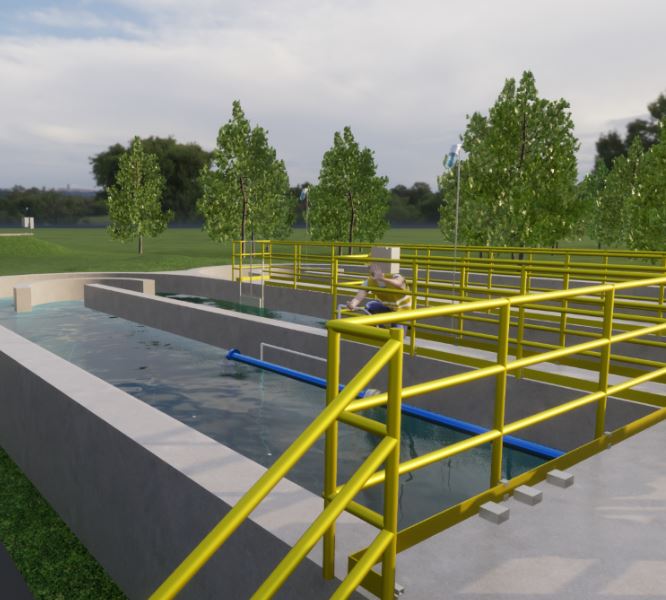

Videos

Revit Video Flythrough: Wastewater Treatment Plant

Take a ride on our flythrough tour of a local wastewater treatment plant pre-construction, created with Revit technology.

...

Read More

One-Pagers

Survey

Learn more about our Survey services via our survey one-pager, which will give you a look at some of the services we offer....

Get the One-Pager

Training

Lead Service Line Replacements – Getting the Lead Out

This video series highlights the step-by-step process of lead service line replacements in Indiana and Ohio....

Learn More

One-Pagers

FOG (Fats, Oils & Grease) Management

Fats, oils and grease (FOG), generated from preparing and cooking food, travel through the wastewater collections system and eventually build up to wreak havoc on pipes, pumps and wastewater treatment plants....

Get the Guide

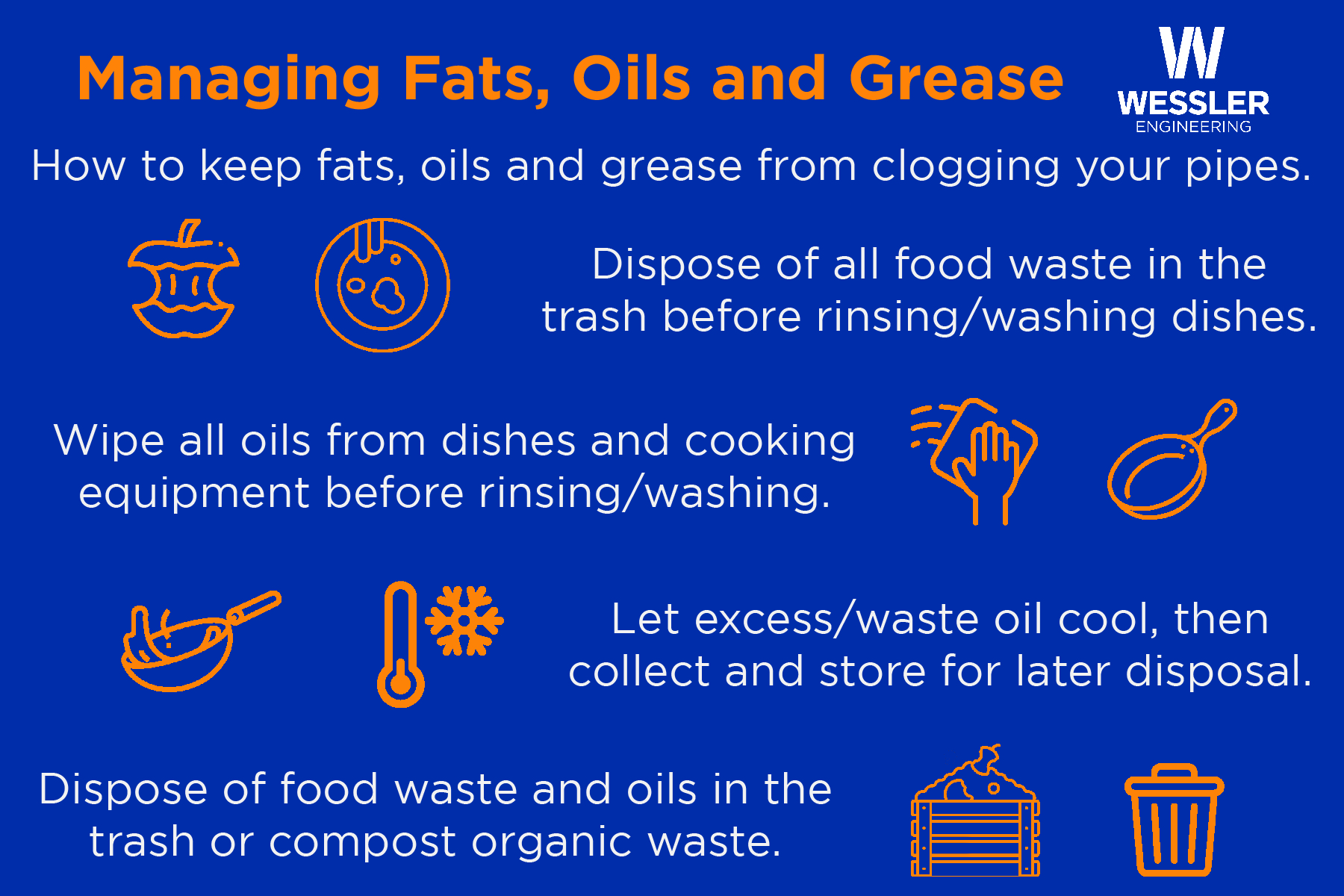

Infographics

Managing Fats, Oils and Grease

Fats, oils and grease (FOG) can wreak havoc on pipes and other wastewater infrastructure if not stored and disposed of properly.

In this infographic, you will learn how to safely store and dispose of FOG at home....

Get the Infographic

Videos

Tunnel Vision: Sewer Camera Services

Trekking through your sewer system doesn't have to be a difficult task. The Rovver X camera provides you with eyes underground, giving you the ability to see sanitary collection systems in real time and help identify problem areas easier than ever.

...

Read More

One-Pagers

Wastewater Treatment

Learn more about our Wastewater Treatment services via our wastewater one-pager, which will give you a look at some of the services we offer....

Get the One-Pager

One-Pagers

Stormwater

Learn more about our Stormwater services via our stormwater one-pager, which will give you a look at some of the services we offer....

Get the One-Pager

One-Pagers

Instrumentation and Controls

Learn more about our Instrumentation & Controls services via our I&C one-pager, which will give you a look at some of the services we offer....

Get the One-Pager

One-Pagers

Field Services

Learn more about our Field services via our field services one-pager, which will give you a look at some of the services we offer....

Get the One-Pager

One-Pagers

Environmental Services

Learn more about our Environmental services via our environmental one-pager, which will give you a look at some of the services we offer....

Get the One-Pager

One-Pagers

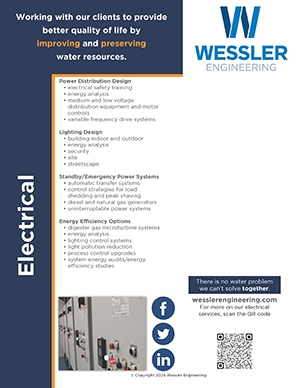

Electrical

Learn more about our Electrical services via our electrical one-pager, which will give you a look at some of the services we offer....

Get the One-Pager

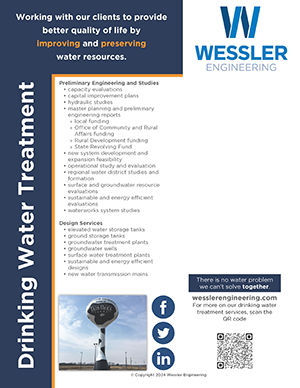

One-Pagers

Drinking Water Treatment

Learn more about our Drinking Water Treatment services via our drinking water one-pager, which will give you a look at some of the services we offer....

Get the One-Pager

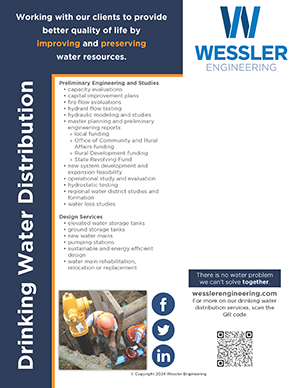

One-Pagers

Drinking Water Distribution

Learn more about our Drinking Water Distribution services via our drinking water one-pager, which will give you a look at some of the services we offer....

Get the One-Pager

One-Pagers

Construction Services

Learn more about our Construction services via our construction one-pager, which will give you a look at some of the services we offer....

Get the One-Pager

One-Pagers

Tunnel Vision: Sewer Camera Services

Our RovverX camera gives you the ability to see sanitary collection systems in real time and help identify problem areas easier than ever....

Get the One-Pager

One-Pagers

Water Loss Audits

Compliance. Understanding. Communication. Those three steps are the bedrock of the water loss audits process. While all of those may seem daunting, breaking each down into their own processes helps simplify a once arduous-seeming task....

Get the One-Pager

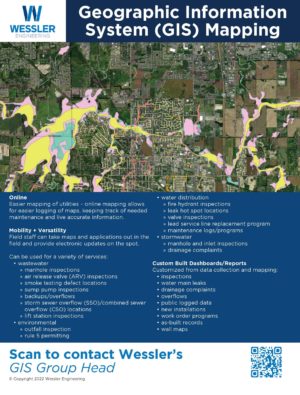

One-Pagers

Geographic Information System (GIS) Mapping

Keeping your GIS updated is an integral step in upkeeping public records. Whether making updates means performing field work to mark new locations, or digitizing hard copies, GIS mapping does not need to be a daunting task....

Get the One-Pager

One-Pagers

Environmental Sustainability

Green/Environmental sustainability are integral parts of civil engineering projects. Here are the steps that can be taken to ensure green principles are implemented in as many projects as possible....

Get the One-Pager

One-Pagers

Design Services – Revit and AutoCAD

To help ensure clients’ water projects are safe + managed + future-proof, design services are used to not only plan and create projects, they serve as a future view of them. Projects come to life by creating conceptualizations in various design software, such as AutoCAD and Revit....

Get the One-Pager

One-Pagers

MS4 Regulations

The Indiana Department of Environmental Management (IDEM) has eliminated the MS4 permit by rule and adopted an MS4 General Permit, requiring MS4 staffs to alter their MS4 program to comply with the new permit requirements....

Get the One-Pager

One-Pagers

The New Lead and Copper Rule

The new Lead and Copper Rule (LCR) requirements that have been published by the Environmental Protection Agency (EPA). These new LCR changes will have significant impact on communities that have lead service lines within their drinking water system....

Get the One-Pager

Training

The New Lead and Copper Rule

Kurt Wanninger, MBA and Senior Project Manager in the Drinking Water group at Wessler, has more than 30 years of professional experience in the water, wastewater and stormwater utility industry as well as more than 16 years in municipal government. In this webinar, Kurt, in conjunction with Jeff Rowe, CPA of Baker Tilly, discusses information on the new Lead and Copper Rule (LCR) requirements have been published by the Environmental Protection Agency (EPA). These new LCR changes will have significant impact on communities that have lead service lines within their drinking water system. Some of the hurdles he covers include:

-

communities will need to inventory their service line materials

-

community water systems will need to increase the quantity of lead and copper sampling

-

communities will need to develop a lead service line replacement plan

-

lastly, these new LCR changes may significantly burden a community financially.

SEE TRAINING VIDEO

Videos

The New Lead and Copper Rule

Kurt Wanninger, MBA and Senior Project Manager in the Drinking Water group at Wessler, has more than 30 years of professional experience in the water, wastewater and stormwater utility industry as well as more than 16 years in municipal government. In this webinar, Kurt, in conjunction with Jeff Rowe, Partner at Baker Tilly, discusses information on the new Lead and Copper Rule (LCR) requirements that have been published by the Environmental Protection Agency (EPA). These new LCR changes will have significant impact on communities that have lead service lines within their drinking water system. Some of the hurdles they cover include:

-

communities will need to inventory their service line materials

-

community water systems will need to increase the quantity of lead and copper sampling

-

communities will need to develop a lead service line replacement plan

-

lastly, these new LCR changes may significantly burden a community financially.

Read More

![[MS4 Training] New MS4 General Permit Plan Review Requirements](https://www.wesslerengineering.com/wp-content/uploads/2021/03/MS4-General-Permit-Plan-Review-Requirements-Training.jpg)

Videos

[MS4 Training] New MS4 General Permit Plan Review Requirements

In this webinar, Environmental Services Project Manager Nancy Cho discusses the upcoming new construction stormwater and MS4 draft general permits. The new permits mean significant changes to the plan review process for new development and redevelopment, including:

- stormwater pollution prevention plans (SWPPPs) will need to include additional information

- MS4s will need to update their ordinances and standards

- new post-construction requirements will require additional technical review of stormwater quantity and quality

Read More

Videos

Wessler 45th Anniversary Company Timeline

To celebrate our 45th anniversary, our team created a video timeline of our journey through the past 45 years in business.

View the video above to take stroll through our company's history and celebrate 45 great years!

...Read More

Videos

MS4 Training – Identifying Wetlands for Project Planning and Plan Review

In this webinar, Environmental Services Project Manager Nancy Cho discusses how wetlands perform ecologically, as well as how they perform flood prevention and stormwater quality functions. Impacts to wetlands are regulated by federal, state and local regulations. This webinar will help MS4s understand the process of identifying wetlands, avoiding impacts during maintenance activities and permitting wetland impacts for public projects. This session also will help MS4s identify potential wetlands during Rule 5 and drainage plan reviews.

For more information or if you have any questions, please contact Nancy Cho at NancyC@wesslerengineering.com or by phone at 317-788-4551....

Read More

Videos

How to Improve Your Community’s Public Protection Classification

How to improve your public protection classification & lower insurance rates.

Senior Project Manager at Wessler, Stan Diamond has helped numerous communities develop hydraulic models of their water distribution systems and then has used those models to help them identify and prioritize needed improvements. Early on, a colleague gave Stan an Insurance Services Office's (ISO) hydrant flow test report and suggested he use the test results to validate the performance of a hydraulic model.

Stan found that not only was the ISO's information useful for validating the model, but it was also useful for identifying the water distribution system deficiencies. After learning more about how the ISO uses their hydrant flow test results and other factors to establish our community's Public Protection Classifications, and getting a better understanding of the impact that those classifications have on insurance rates, Stan has become passionate about educating others on what they can do to improve their water distribution systems, raise their community's public protection classifications, and bring down their insurance rates....

Read More

Videos

Replacement or Rehabilitation?

A summary of sanitary sewer replacement and rehabilitation alternatives and technologies, as well as the evaluation of several scenarios that compare the economics of replacement costs to the costs of rehabilitation.

In this webinar, Senior Project Manager Ryan Brauen, P.E., provides a summary of sanitary sewer replacement and rehabilitation alternatives and technologies. He evaluates several scenarios to compare the economics of replacement costs compared to rehabilitation costs. Ryan's goal was for listeners to leave this presentation with a better understanding of sanitary sewer replacement and rehabilitation alternatives, ancillary cost considerations, and have a better understanding of improvement options when evaluating future repair work in their collection systems....

Read More

Training

GHS of Classification

Reviews the new labeling and SDS requirements of OSHA.

GHS Webinar- The webinar reviews the new labeling and SDS requirements of OSHA’s Hazard Communication Program.

If your employees frequently handle chemicals or are around chemicals at sites or plants, they will need training on the new Global Harmonization System (GHS) requirements for labeling and Safety Data Sheets (SDS).

Do you or your employees need to be trained? Let Wessler help! The webinar reviews the new labeling and SDS requirements of OSHA’s Hazard Communication Program.

The websites referenced during the webinar:

Supplemental Information

OSHA’s Hazard Communication

University of Nebraska

Fish Consumption Advisory...

SEE TRAINING VIDEO

Videos

GHS of Classification

Reviews the new labeling and SDS requirements of OSHA.

GHS Webinar- The webinar reviews the new labeling and SDS requirements of OSHA’s Hazard Communication Program.

If your employees frequently handle chemicals or are around chemicals at sites or plants, they will need training on the new Global Harmonization System (GHS) requirements for labeling and Safety Data Sheets (SDS).

Do you or your employees need to be trained? Let Wessler help! The webinar reviews the new labeling and SDS requirements of OSHA’s Hazard Communication Program.

The websites referenced during the webinar:

Supplemental Information

OSHA’s Hazard Communication

University of Nebraska

Fish Consumption Advisory...

Read More

Videos

Avoiding the Emergency Room

Engineer Nick Lyons discusses the daunting tasks of managing and maintaining a sewer system. However, like our own human health, a structured plan for preventative care is simpler and often less expensive than a trip to the emergency room. This presentation describes the steps of forming an asset management plan (AMP) to promote the health and longevity of a sewer system and reduce long-term costs. These steps include performing “check-ups” to investigate a sewer system’s condition, assessing the system’s “medical history” to prioritize maintenance and repairing and rehabilitating sewer systems when required.

...

Read More

Training

6 Steps to Performing a Smoke Test

The theory behind smoke testing is: where smoke's getting out, water is getting in.

In this video, Wessler Engineering is on site smoke testing a sanitary sewer system to locate and identify defects that are contributing to inflow infiltration. The theory behind smoke testing is: where smoke's getting out, water is getting in. Visit here to read about the 6 Steps!...

SEE TRAINING VIDEO

Videos

6 Steps to Performing a Smoke Test

The theory behind smoke testing is: where smoke's getting out, water is getting in.

In this video, Wessler Engineering is on site smoke testing a sanitary sewer system to locate and identify defects that are contributing to inflow infiltration. The theory behind smoke testing is: where smoke's getting out, water is getting in. Visit here to read about the 6 Steps!...

Read More

Videos

Intro to SCADA – Basic Component Functions and Architecture

Information on what SCADA is, as well as its functions and components.

Shawn Perkins, P.E. and Senior Project Manager in the Electrical Group at Wessler, specializes in Instrumentation & Controls, SCADA design, and implementation. In this webinar, Shawn discusses information on SCADA systems (Supervisory Control and Data Acquisition). You will find out why SCADA is known as "mission control" by learning about the benefits of SCADA, how it interacts with control systems to regulate processes, what makes up the components of a PLC/HMI system, and how all of these components work together to create a more unified control system. You will also gain a better understanding of the equipment, hardware, software and industry terminology used with SCADA....

Read More

Videos

MS4 Training – Pollution Prevention & Good Housekeeping Part II

Pollution Prevention and Good Housekeeping Part II: A virtual Municipal Facility Inspection- We took participants step-by-step through a real municipal facility inspection. Participants learned how to identify and document deficiencies, as well as recommend corrective actions.

We held a "virtual inspection" webinar last week and were thrilled with the level of participation. In the webinar, we took participants step-by-step through a real municipal facility inspection. Participants learned how to identify and document deficiencies, as well as recommend corrective actions.

The webinar satisfies one program requirement just by participating (annual Municipal Employee Training). If you missed the live event, we have posted the recording below for you to watch at your convenience. Don't forget to download this blank checklist with completed examples to aid in your training and evaluation process....

Read More

Training

MS4 Training – Pollution Prevention & Good Housekeeping Part II

Pollution Prevention and Good Housekeeping Part II: A virtual Municipal Facility Inspection- We took participants step-by-step through a real municipal facility inspection. Participants learned how to identify and document deficiencies, as well as recommend corrective actions.

We held a "virtual inspection" webinar last week and were thrilled with the level of participation. In the webinar, we took participants step-by-step through a real municipal facility inspection. Participants learned how to identify and document deficiencies, as well as recommend corrective actions.

The webinar satisfies one program requirement just by participating (annual Municipal Employee Training). If you missed the live event, we have posted the recording below for you to watch at your convenience. Don't forget to download this blank checklist with completed examples to aid in your training and evaluation process....

SEE TRAINING VIDEO

Videos

MS4 Training – For Construction and Post Construction MCMs 4 and 5

Are You Prepared for Inspections and Enforcement?

This training webinar will help you prepare for SWPPP inspections of active construction sites, inspection of post-construction BMPs, and enforcement actions that might be associated with those inspections....

Read More

Training

MS4 Training – For Construction and Post Construction MCMs 4 and 5

Are You Prepared for Inspections and Enforcement?

This training webinar will help you prepare for SWPPP inspections of active construction sites, inspection of post-construction BMPs, and enforcement actions that might be associated with those inspections....

SEE TRAINING VIDEO

Training

Oil, Chemical & Waste Handling

Training for municipal employees for handling of management of used oils, chemicals, universal and electronic wastes. During this webinar the following topics will be discussed:

- Used oil collection and handling

- General chemical handling and storage practices

- Spill prevention

- Universal Waste

- Electronic Waste

SEE TRAINING VIDEO

Videos

Oil, Chemical & Waste Handling

Training for municipal employees for handling of management of used oils, chemicals, universal and electronic wastes. During this webinar the following topics will be discussed:

- Used oil collection and handling

- General chemical handling and storage practices

- Spill prevention

- Universal Waste

- Electronic Waste

Read More

Training

Wellhead Protection Training for Utility Employees

This webinar reviews information such as securing the wells, preventing spills from happening around the wells, and responding to spills or contamination should they occur within the wellhead protection area or distribution system.

If your community has a Wellhead Protection Plan to protect the wells and drinking water source, your utility employees are required to have periodic training. Think about where your wells are located and who is working around those wells -- employees from the water utility, parks department and street department? Do these employees need to be trained?

Let Wessler Engineering help! We presented a webinar (recording below) on Wellhead Protection Training for Utility Employees, and many attendees asked us to make this available for others. The webinar reviews information such as securing the wells, preventing spills from happening around the wells, and responding to spills or contamination should they occur within the wellhead protection area or distribution system.

During the live webinar, there were questions about how to regulate activities in the wellhead protection area. The Indiana Department of Environmental Management's website (Additional Wellhead Protection Provisions in Other Rules) has a listing of regulations, other than the wellhead protection rule, that are in place....

SEE TRAINING VIDEO

Videos

Wellhead Protection Training for Utility Employees

This webinar reviews information such as securing the wells, preventing spills from happening around the wells, and responding to spills or contamination should they occur within the wellhead protection area or distribution system.

If your community has a Wellhead Protection Plan to protect the wells and drinking water source, your utility employees are required to have periodic training. Think about where your wells are located and who is working around those wells -- employees from the water utility, parks department and street department? Do these employees need to be trained?

Let Wessler Engineering help! We presented a webinar (recording below) on Wellhead Protection Training for Utility Employees, and many attendees asked us to make this available for others. The webinar reviews information such as securing the wells, preventing spills from happening around the wells, and responding to spills or contamination should they occur within the wellhead protection area or distribution system.

During the live webinar, there were questions about how to regulate activities in the wellhead protection area. The Indiana Department of Environmental Management's website (Additional Wellhead Protection Provisions in Other Rules) has a listing of regulations, other than the wellhead protection rule, that are in place....

Read More

Training

MS4 Training – Pollution Prevention & Good Housekeeping Part I

MS4 Good Housekeeping Do’s and Don’t’s- focus on municipal facility general good housekeeping and pollution prevention as it pertains to the Municipal Separate Storm Sewer System (MS4) Program – Minimum Control Measure (MCM) #6.

The training event will focus on municipal facility general good housekeeping and pollution prevention as it pertains to the Municipal Separate Storm Sewer System (MS4) Program – Minimum Control Measure (MCM) #6.

MS4 communities are required to document employee training on topics such as chemical handling practices, fueling operations, spill prevention, vehicle maintenance and other general good housekeeping practices. This webinar will serve as that required training....

SEE TRAINING VIDEO

Training

MS4 Training – Implementing Your MS4 Program During Winter Weather Months

Jacob Barker is an assistant project manager in our Environmental Services Group. Viewers will receive training on a variety of topics concerning the implementation of the MS4 Program during winter weather months, spanning all six Minimum Control Measures. The webinar will provide viewers an opportunity to fulfill their annual MS4 training requirement....

SEE TRAINING VIDEO

Training

MS4 Training – Illicit Discharge Detection & Elimination Webinar

The purpose of this webinar is to identify and provide examples of commonly encountered illicit discharges, discuss various methods and means available to assist with the elimination of illicit discharges, and to provide guidance for IDDE program compliance documentation. Wessler has developed an IDDE Field Guide to assist MS4 personnel with illicit discharge identification, elimination, and documentation. This field guide is available for download here.

The webinar will provide viewers an opportunity to fulfill their annual MS4 training requirement....

SEE TRAINING VIDEO

Videos

MS4 Training – Illicit Discharge Detection & Elimination Webinar

The purpose of this webinar is to identify and provide examples of commonly encountered illicit discharges, discuss various methods and means available to assist with the elimination of illicit discharges, and to provide guidance for IDDE program compliance documentation. Wessler has developed an IDDE Field Guide to assist MS4 personnel with illicit discharge identification, elimination, and documentation. This field guide is available for download here.

The webinar will provide viewers an opportunity to fulfill their annual MS4 training requirement....

Read More

Videos

MS4 Training – Implementing Your MS4 Program During Winter Weather Months

Jacob Barker is an assistant project manager in our Environmental Services Group. Viewers will receive training on a variety of topics concerning the implementation of the MS4 Program during winter weather months, spanning all six Minimum Control Measures. The webinar will provide viewers an opportunity to fulfill their annual MS4 training requirement....

Read More

Videos

Cost Savings at the WWTP

In this webinar, Project Engineer Bridget Philpott discusses how a utility's power bill is calculated and the operational changes possible at a treatment plant to reduce the bill.

For more information or if you have any questions, please contact Bridget Philpott at BridgetP@wesslerengineering.com or by phone at 317-788-4551....

Read More

Videos

Case Study: City of Lawrence’s Capital Improvements Planning

Using the City of Lawrence's water system as a case study, Senior Project Manager Dylan Lambermont, PE, LEED AP, explores the areas of: asset management, risk assessments, aging infrastructure, water main replacement program, capacity challenges, funding, design and construction.

For more information or if you have any questions, please contact Senior Project Manager Dylan Lambermont, PE, LEED AP at DylanL@wesslerengineering.com or by phone at 317-788-4551....

Read More

Videos

CSO LTCP Cost Savings Through Green Infrastructure

In this webinar Wessler Engineering's Stormwater group head, Bill Leber, P.E., LEED AP discusses the how green infrastructure can be implemented to slow the rate of runoff, resulting in pipe, storage and treatment facility size reduction, even in areas where soils do not support infiltration....

Read More

Videos

LiDAR and Its Applications

Over the past few years, light detection and ranging (LiDAR) has become more relevant to municipalities. In 2013 the State of Indiana completed a two-year LiDAR survey of the entire State, making elevation data accessible to the public for the first time.

Previously, LiDAR data had been used for specific applications due to the accuracy of the data. Over time, advancements in technology and increased accuracy of the data has expanded LiDAR’s application and has been proven beneficial to municipalities.

This webinar was presented on October 14 by Ryan Sidler....

Read More

Videos

Drone-Assisted Stormwater Site Inspections

Check out Wessler Engineering Environmental Services Project Manager Jacob Barker’s experience with drone technology to assist with construction site stormwater erosion and sediment control inspections. From providing greater access to construction sites, to capturing high resolution photos, to the potential for additional structure and marketing applications and much more, Jake offers his take on the pros and cons of this increasingly popular technology....

Read More

Videos

Water Loss Audit is Done…What can I do with the Information?

Andrew Gordon, P.E., a Project Manager in the Drinking Water Group at Wessler Engineering, discusses the importance of completing a water loss audit, understanding the terminology used in the audit, how to interpret your audit results, and determine ways to reduce non-revenue water in your water system.

Read More

Videos

Reducing Inflow & Infiltration in a Sanitary Collection System

In this Webinar Field Services Manager, Brad Robinson, and Project Engineer, Joe Bartos, discuss why it is important for communities to identify inflow and infiltration, ways municipalities and/ or utilities can identify areas of inflow and infiltration (I/I), and rehabilitation options of Sanitary Collection System to reduce or eliminate I/I....

Read More

Videos

Alternate Sewer Rehab Methods: EXpanding the Toolbox

Wessler Engineering's Kate Hughes, E.I., presents a Citizens Energy Group pilot study using Miller Pipeline’s Expanded in Place sewer rehab method. Kate compares this method to the popular Cured In Place Pipe method - known as CIPP - and also discusses the benefits and limitations of each....

Read More

Videos

Asset Management for Capital Planning

Learn about available tools to complete an asset management evaluation and how the results can be used in capital planning....

Read More

Videos

How to Improve Your Community’s Public Protection Classification

How to Improve Your Community's Public Protection Classification:

Senior Project Manager at Wessler, Stan Diamond has helped numerous communities develop hydraulic models of their water distribution systems and then has used those models to help them identify and prioritize needed improvements. Early on, a colleague gave Stan an Insurance Services Office's (ISO) hydrant flow test report and suggested he use the test results to validate the performance of a hydraulic model. Stan found that not only was the ISO's information useful for validating the model, but it was also useful for identifying the water distribution system deficiencies. After learning more about how the ISO uses their hydrant flow test results and other factors to establish our community's Public Protection Classifications, and getting a better understanding of the impact that those classifications have on insurance rates, Stan has become passionate about educating others on what they can do to improve their water distribution systems, raise their community's public protection classifications, and bring down their insurance rates.

Read More

Infographics

Infographic: Proofreading Your Professional Communications

10 tips for error-free content. This infographic includes reference materials, grammar, and editing.

Get the Infographic

Infographics

Field Services Infographic

When you download this free infographic, you will receive helpful tips about:

- Cost-effective ways to find leaks

- When to smoke test

- The best months for wet weather inspections

- and more!

Get the Infographic

Infographics

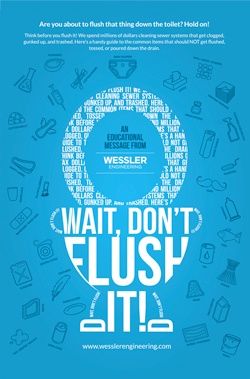

Wait, Don’t Flush That!

Are you about to flush that thing down the toilet? Hold on!

Think before you flush it! We spend millions of dollars cleaning sewer systems that get clogged, gunked up, and trashed. Here’s a handy guide to the common items that should NOT get flushed, tossed, or poured down the drain.

Help spread the word with an educational poster from Wessler Engineering. Hang it in your office restroom or your public facilities....

Get the Free Poster

Case Studies

Greentown, IN Case Study

When a treatment plant reaches or approaches 90% of it’s hydraulic or organic design capacity, Rule 327 IAC 4-1-3 states that IDEM will notify the operator that a Sewer Connection Ban may be necessary.

The Town of Greentown, Indiana experienced these issues during the past decade. Town officials engaged with Wessler to make major improvements to their collection and waste treatment systems.

The following case study is an overview of a project in Greentown, Indiana that began in 2005 and continued through 2014.

Learn how the Town was eventually released from the Sewer Ban and the Agreed Order, and how the capital improvements they made led to greater energy savings and efficiencies.

Download the full Case Study to learn more about this extensive project. ...

GET THE CASE STUDY

Case Studies

City of Beech Grove Case Study

This case study highlights the benefits to the City of Beech Grove from revising their flood rate maps and includes:

- Concerns the Beech Grove residents had

- Actions taken to address concerns

- Results achieved

- Insight into working with Wessler Engineering

Get the Case Study

Publications

Cogeneration Implementation Guide for Wastewater Treatment Plants

Featured in Indiana Water Environment Association's Winter 2015 issue of The Digester. This article explores cogeneration fundamentals....

Download the Publication

Publications

Eleven Steps to a Healthier Sanitary Sewer System

Featured article in The Digester. As Benjamin Franklin is famous for saying, “An ounce of prevention is worth a pound of cure.” The health of your sanitary sewer system is similar to our personal health. Maintain your sewers and you can minimize costly repairs. Read our Eleven Steps to a Healthier Sanitary Sewer System....

Download the Publication

Publications

Plant Profile: Frankfort Wastewater Treatment Plant- 1929 to Present

Featured in Indiana Water Environment Association's Spring 2012 issue of The Digester. The City of Frankfort, Indiana was founded in 1830. The WWTP serves a population of approximately 17,000 including the unincorporated community of Jefferson and a heavy industrial base. Read more about the history of the city’s WWTP and the improvement efforts in recent decades....

Download the Publication

Publications

Innovative Solutions: Bryan’s Lift Station and CSO Storage System – City of Monticello, Indiana

The City of Monticello, Indiana owns and operates a combined sewer collection system and a Class II wastewater treatment plant (WWTP) with a design average flow of 1.1 MGD and a peak capacity of 2.4 MGD. The collection system has six combined sewer overflow (CSO) outfalls which discharge to the Tippecanoe River and Lake Freeman, a popular recreational water body. Read about the City’s long-term control plan and completion of Phase I of the Bryan’s Lift Station Improvement Project....

Download the Publication

Publications

Planning, Preparation Pays Off in Indianapolis

Featured project in the September/October 2010 issue of Engineering Inc. At 1.2 million square feet, there is nothing small about the Indianapolis International Airport’s Midfield Terminal. The massive construction project was so complex that planning for the original design began more than 30 years ago.

It wasn’t until 1999 that Wessler Engineering was given the green light to move forward on an ambitious effort to cost-effectively manage water-quality treatment and aircraft deicing for the facility.

...

Download the Publication

Guides

How to Implement a Municipal Pretreatment Program

Receive helpful tips relevant to implementing a municipal pretreatment program, such as

...

- Tasks to complete

- Industrial compliance tips

- And more

Get the Guide

Guides

Key Elements for Creating a Stormwater Utility

Learn more about creating a Stormwater Utility, including:

...

- Utility benefits

- Education

- And more

Get the Guide

Guides

WWTP Operations 101: WWTP Operational Data

This guide includes information relevant to the operations of a WWTP, such as:

...

- Understanding calculations

- Data Management

- And more

Get the Guide

Guides

Dangers of Elevated Nitrates and How to Reduce Them

This information-packed guide includes:

...

- What causes nitrates

- How to protect yourself

- And more

Get the Guide

Guides

Backup and Restore: A Guide for Creating Industrial Backup Procedures

This Guide walks through the who, what, when, where and how questions that must be addressed in industrial Backup and Restore Procedures.

Get the Guide

Guides

Where’s Your Waste?

A Municipality's Guide to Handling Used Oil, General Chemicals, Universal Waste and Electronic Waste....

Get the Guide

Guides

The Cogeneration Implementation Guide for Wastewater Treatment Plants

This information-packed guide includes:

...

- What cogeneration is and how it works for a WWTP

- The energy cycle in a cogen system (with diagram)

- And more

Get the Guide

Guides

Helpful Hints for EPCRA

This information-packed guide includes:

...

- Conducting an inventory

- Determining if the chemical is reportable

- And more

Get the Guide

Guides

Guide to CSO Operational Plans

This information-packed guide includes:

...

- Information to include in your plan

- How to structure your plan

- And more

Get the Guide

Guides

Engineering 101: Working With Your Consulting Engineer

This guide includes information on how your consulting engineer can assist you with:

...

- Defining project phases

- Evaluating solutions

- And more.

Get the Guide

Training

MS4 Training – Identifying Wetlands for Project Planning and Plan Review

In this webinar, Environmental Services Project Manager Nancy Cho discusses how wetlands perform ecologically, as well as how they perform flood prevention and stormwater quality functions. Impacts to wetlands are regulated by federal, state and local regulations. This webinar will help MS4s understand the process of identifying wetlands, avoiding impacts during maintenance activities and permitting wetland impacts for public projects. This session also will help MS4s identify potential wetlands during Rule 5 and drainage plan reviews.

For more information or if you have any questions, please contact Nancy Cho at NancyC@wesslerengineering.com or by phone at 317-788-4551....

SEE TRAINING VIDEO

Infographics

What Are Compact Fluorescent Light Bulbs?

Discover what Wessler Engineering can teach you about the importance of compact fluorescent bulbs.

In this infographic, you will learn:

...

- Diagrams and definitions of CFLs/fluorescent blubs

- What makes them work

- How to avoid breakage

- The importance of recycling

Get the Infographic

Videos

MS4 Training – Pollution Prevention & Good Housekeeping Part I

MS4 Good Housekeeping Do’s and Don’t’s- focus on municipal facility general good housekeeping and pollution prevention as it pertains to the Municipal Separate Storm Sewer System (MS4) Program – Minimum Control Measure (MCM) #6.

The training event will focus on municipal facility general good housekeeping and pollution prevention as it pertains to the Municipal Separate Storm Sewer System (MS4) Program – Minimum Control Measure (MCM) #6.

MS4 communities are required to document employee training on topics such as chemical handling practices, fueling operations, spill prevention, vehicle maintenance and other general good housekeeping practices. This webinar will serve as that required training....

Read More

Case Studies

Case Study: Merrill Street Combined Sewer Rehabilitation

The City of Indianapolis operates an extensive sewer collection system to serve the metropolitan area. As sewers near the wastewater treatment plants, they grow larger in diameter and are more critical to operation. In the summer of 2007, Wessler Engineering was tasked with designing a solution for a portion of the Pogues Run Relief Interceptor (hereinafter known as the Merrill Street Sewer), which is a critical large diameter combined sewer in the heart of downtown Indianapolis. The City’s concern for this particular sewer was twofold: first, it was approaching 60 years in age and had experienced a number of operational issues, and second, that it could limit capacity for the main campus of Eli Lilly & Company, the City’s largest and most visible taxpayer. Wessler’s job was to put a new sewer in place that would increase capacity and extend the service life, while limiting cost and construction disturbance.

Download the full Case Study to learn more about this extensive project. ...

Get the Case Study

Publications

Uh Oh, I Received a Letter from IDEM

Most municipal wastewater and drinking water treatment plants received letters from the Indiana Department of Environmental Management (IDEM), Office of Air Quality (OAQ) in March or April. Now, you might be thinking that you only deal with water, so things dealing with the air do not apply to you. But they do. Read the full article in this issue of The Digester....

Download the Publication

Guides

Guide to SPCC Planning

This information-packed guide includes:

...

- Who is regulated

- Building your plan

- Spill prevention

- And more

Get the Guide